Hello Everyone.

I just registered here and I'd like to share with you as system which is becoming very popular here in Indonesia.

It's known as HCS (for Hydrocarbon Crakcing System) and is very simple and cheap to make and install oneself.

Huge mileage and power increases have been experienced with this system.

It there is already a thread discussing this system or if I have chosen to post this in the wrong section; I hope that someone will correct me.

I should also point out that this system is not patented and is firmly in the public domain.

My own interest in it is completely without commercial aspirations of any kind.

Here is a simple schematic of the system:

There are a couple of minor variations of the system but this one shows it in its basic form.

Air is drawn through a bubbler tank which is about 30% filled with regular gasoline.

As the bubbles agitate the fuel; it partially evaporates and the fuel-rich vapours are then drawn through a 'catalyst' which is clamped to the outside of the hottest part of the exhaust pipe; heating it to around 300 degrees celsius.

At these temperatures; the fuel vapour is cracked into Hydrogen and Carbon and is drawn on into the vacuum intake of the engine.

This schematic shows a Manifold vacuum which is not the best form of vacuum for this system.

The reason being that the Manifold vacuum is strongest at idle and diminishes rapidly as the throttle is opened and the engine speed picks up.

Far better is the Venturi vacuum which increases with the speed of the engine drawing increasing quantities of hydrogen as it is needed.

However; many engines do not have a readily available Venturi vacuum and this is a persistent problem vacuum-operated HCS.

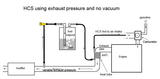

Another way of operating the system is to push the vapours through the bubbler and 'catalyst' and on into the engine.

If pressure is used; the output can be fed into the air filter or the Manifold vacuum which greatly increases the ease of fitting the system.

There are a couple of obvious variable pressure sources available for out purposes.

One is the Exhaust system and the other is the PCV pipe.

Both are beneficial when drawn into the burn chamber of the engine and both increase and decrease with the speed of the engine.

Another benefit of using exhaust or PCV is that they are warm and will greatly aid the evaporation of the bubbler fuel.

Here is an exhaust pressure scheme:

Here is a PCV pressure scheme:

I hasten to add that the pressure needed to push the vapours through the system is very low and pose no danger at all.

I am currently running my Ford 2.5 liter fuel injected petrol car with this system attached.

It is operated by a venturi vacuum that I was fortunate enough to discover.

The run of the engine is much smoother and quieter that without and the power is noticeably greater.

I have experienced a 20% mileage increase in town driving and 40% increase in out-of-town driving.

I also run an exhaust-pressure HCS on my Honda 200cc motorcycle feeding the output into the manifold vacuum.

The run of the engine is smoother and quieter with noticeably increased power.

Mileage increases have yet to be calculated as it is used occasionally on short town runs.

Finally; I run a PCV pressure HCS on my Kawasaki 250cc twin.

The engine is quieter and smoother with noticeably increased power and around 40% mileage increase in regular town driving.

Dan.