This is one of my long list of projects that I've been working on around the house. I haven't had much time to work on the car/gassaving etc because of the project list. Which included a home birth 2/29 and renovating the basement.

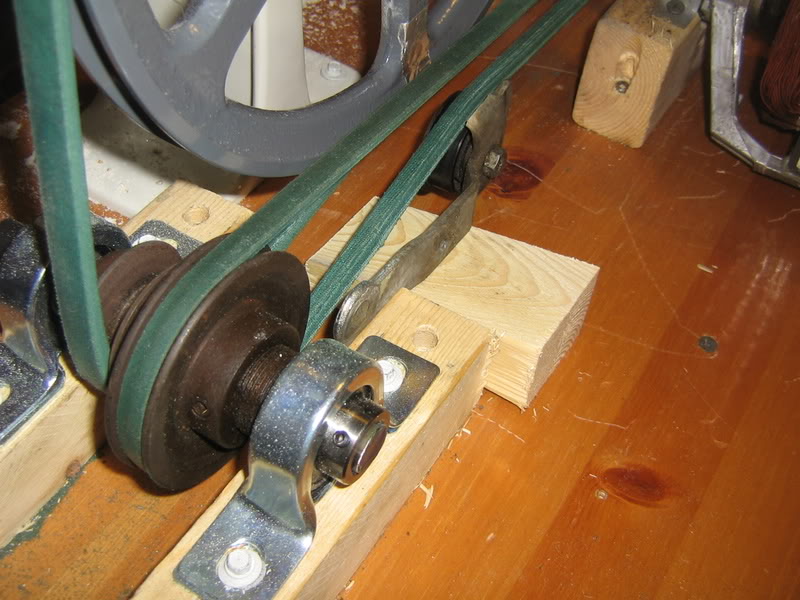

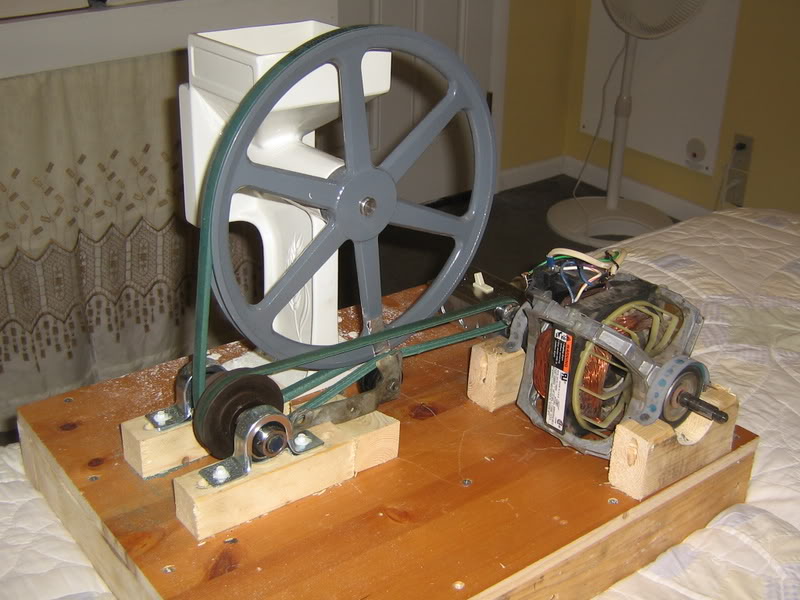

I got my grain mill in last week and it only took me about an hour of hand cranking to realize I was going to motorize it. It came equipped with a 12" flywheel with a v belt groove built in. I scrounged the motor and pulleys, bought the bearings from the local grainger store, the wood I scavenged off the road, the belts and shaft I bought locally.

Its a Country Living Mill. It uses large steel burrs for grinding. The current motor is a recycled dryer motor the runs 1750rpms its reduced to 84rpms at the mill.

This is the original pulley that came on the dryer motor. It started life about 9/16" wide 5 ribs. I used a flux core mig welder to add material and reduce its width. I then ran the motor and crudely turned milled it to shape using an angle grinder, dremel, and file. Its now sized for a 3/8" V belt.