|

|

05-24-2009, 10:37 AM

05-24-2009, 10:37 AM

|

#1

|

|

Registered Member

Join Date: Mar 2009

Posts: 1,139

Country: United States

|

Interfacing 6" Flange to Metal Roof

I am installing a 6" insulated chimney and the flange used is really meant for a shingled roof, whereas mine is metal. Talked to the local hardware places and all their solutions for how to interface it involve tons of caulk and will be ugly as sin. I expected a custom adapter but was told there isn't one. Going from the roofing to the flange is easy, but transitioning back on again is the problem because of the corrugations. The flange would hit at least two of the tall ribs (three if positioned carelessly). I have a lot of scrap roofing that I can use and have a few ideas, such as cutting a hole in some roofing and welding the flange to it. That one's pretty brute force and would require some accurate trimming. Another is to create custom angled transition pieces to slope the water up onto the flange and then back down again on the other side. The flange could then stay above the height of the ribs altogether. I have a sheet metal brake so that's not so tough. Any ideas? Thanks.

Here's a picture of the metal roofing pattern in question (not that color, but I was too lazy to snap my own photo).

__________________

Main Entry: co de pen dence

Main Entry: co de pen dence - see codependency

co de pen den cy

Pronunciation: \kō-di-ˈpen-dən(t)-sē\

Function: noun

Date: 1979

: a psychological condition or a relationship in which a person is controlled or manipulated by another who is affected with a pathological condition (as an addiction to alcohol or heroin) ; broadly : dependence on the needs of or control by another

|

|

|

05-24-2009, 01:02 PM

05-24-2009, 01:02 PM

|

#2

|

|

Registered Member

Join Date: Nov 2006

Posts: 1,027

Country: United States

|

Here's my 2 cents:

How about using one of these:

Put the grommet under the metal roofing and carefully trim the metal ribs to match the taper angle of the grommet- just leave a small channel on the uphill side for water to escape or slit and flatten the last 2 inches of the uphill ribs so they can't form a dam.

Then caulk the 1/8" or so all around with butyl caulk- it's much better than latex or silicone and lasts forever- just don't get it on your hands- it's a real sticky mess to clean off of your skin.

This method will require some careful trimming. Maybe you could just cut the hole in the metal roofing square and then on the downhill side, cut some 4 inch rib lengths with the right taper on the ends that match the taper of the metal grommet and caulk them on.

|

|

|

05-24-2009, 01:10 PM

05-24-2009, 01:10 PM

|

#3

|

|

Registered Member

Join Date: Mar 2009

Posts: 1,139

Country: United States

|

The flange I have now is very similar in nature to those, just with a square flat piece attached as well. I've never worked with butyl caulk. Be a lot easier than welding, that's for sure. More forgiving on the closeness of cut as well. I'm pretty good at that sort of precision work and I have a bunch of pieces so messing up wouldn't be the end of the world.

__________________

Main Entry: co de pen dence

Main Entry: co de pen dence - see codependency

co de pen den cy

Pronunciation: \kō-di-ˈpen-dən(t)-sē\

Function: noun

Date: 1979

: a psychological condition or a relationship in which a person is controlled or manipulated by another who is affected with a pathological condition (as an addiction to alcohol or heroin) ; broadly : dependence on the needs of or control by another

|

|

|

05-24-2009, 03:17 PM

05-24-2009, 03:17 PM

|

#4

|

|

Registered Member

Join Date: Mar 2009

Posts: 1,139

Country: United States

|

I thought some pictures might help things a bit. The top drawing is what I'm calling the "under" option. It relies on some reliable method of sealing (let's assume that's butyl caulk) and some close cutting. The bottom drawing is the "over" method and in theory could work purely with downhill joints (I've shortened all the overlaps considerably to shrink the drawing to fit). Now that I think about it, that top piece could just be the edge of the flange bent to that shape, rather than a whole separate part. The flange is pretty long. Seems obvious...now. Wait a sec...how does that work at the boundaries where the flange stops? Have to draw some more pictures to get a feel for the geometry.

The under option would arguably be more attractive, since the roof's color (slate blue) would be preserved except for the sleeve itself. I guess I could paint the flat part of the flange in the over option. It's actually quite large, which is good from an overlap perspective to keep out the wind driven rain (which we get in plenty here).

__________________

Main Entry: co de pen dence

Main Entry: co de pen dence - see codependency

co de pen den cy

Pronunciation: \kō-di-ˈpen-dən(t)-sē\

Function: noun

Date: 1979

: a psychological condition or a relationship in which a person is controlled or manipulated by another who is affected with a pathological condition (as an addiction to alcohol or heroin) ; broadly : dependence on the needs of or control by another

|

|

|

05-24-2009, 07:16 PM

05-24-2009, 07:16 PM

|

#5

|

|

Registered Member

Join Date: Mar 2009

Posts: 1,139

Country: United States

|

Drew some more pictures and realized that it could work exactly the same with my metal roof as with a shingled one except for the downhill ridges. To solve this, I can cut out slots in the flange where the ridges are (including small areas in the cone edge), then attach and caulk in a piece of roofing material, essentially adding those corrugations to the flange. I think welding something that thin is beyond my amateur skills (especially without gas), so I'm thinking rivets and caulk (my spot welder has croaked). The joint is theoretically downhill, so it's much less of a caulking challenge than it could be. I tried to draw this up a bit (scale is more than a little off, but you get the gist). Dark blue is roofing on top, grey is flange on top, light blue is flange underneath roofing. The red lines are where the slots would have to be cut in the original flange. This should work extremely well and can be constructed before heading up on the roof - always a plus. I'll paint the piece of roofing I add to the flange silver to match before I caulk it in place. Neatness counts; at least it does if you ever plan to resell.

__________________

Main Entry: co de pen dence

Main Entry: co de pen dence - see codependency

co de pen den cy

Pronunciation: \kō-di-ˈpen-dən(t)-sē\

Function: noun

Date: 1979

: a psychological condition or a relationship in which a person is controlled or manipulated by another who is affected with a pathological condition (as an addiction to alcohol or heroin) ; broadly : dependence on the needs of or control by another

|

|

|

05-25-2009, 04:39 AM

05-25-2009, 04:39 AM

|

#6

|

|

Registered Member

Join Date: Apr 2008

Posts: 6,624

Country: United States

|

There is a correct way to do this, and it's easy. I used to be in the roofing business in my dad's company and we did a couple Standing Seam metal roofs. BTW, "standing seam" is the term you should use in google while looking for how to do it.

I say that it's easy because I know that roofers don't like difficult stuff. I've met plenty of them, owners of roofing companies, supervisors, grunts, and family members. None of them wants anything remotely complicated. The grunts tend to be folks who couldn't get a job that sucks less (sorry if I'm offending anyone here, but I'm reporting what I learned growing up in the business and working in it for five years). The folks in charge don't want something easy to screw up, because it costs a lot to go back and fix stuff and it has to last for decades - with standing seam metal it has to last for 40 years or more.

The point of telling you all that is so you'll believe this: You're expending far too much effort. If I remember correctly, for a 6" flashing you'll need to fabricate something from sheet metal; but there's already a standard design and all you'd need to do is scale the design and cut it.

I'll ask my dad, he might remember.

__________________

This sig may return, some day.

|

|

|

05-25-2009, 05:59 AM

05-25-2009, 05:59 AM

|

#7

|

|

Registered Member

Join Date: Mar 2009

Posts: 1,139

Country: United States

|

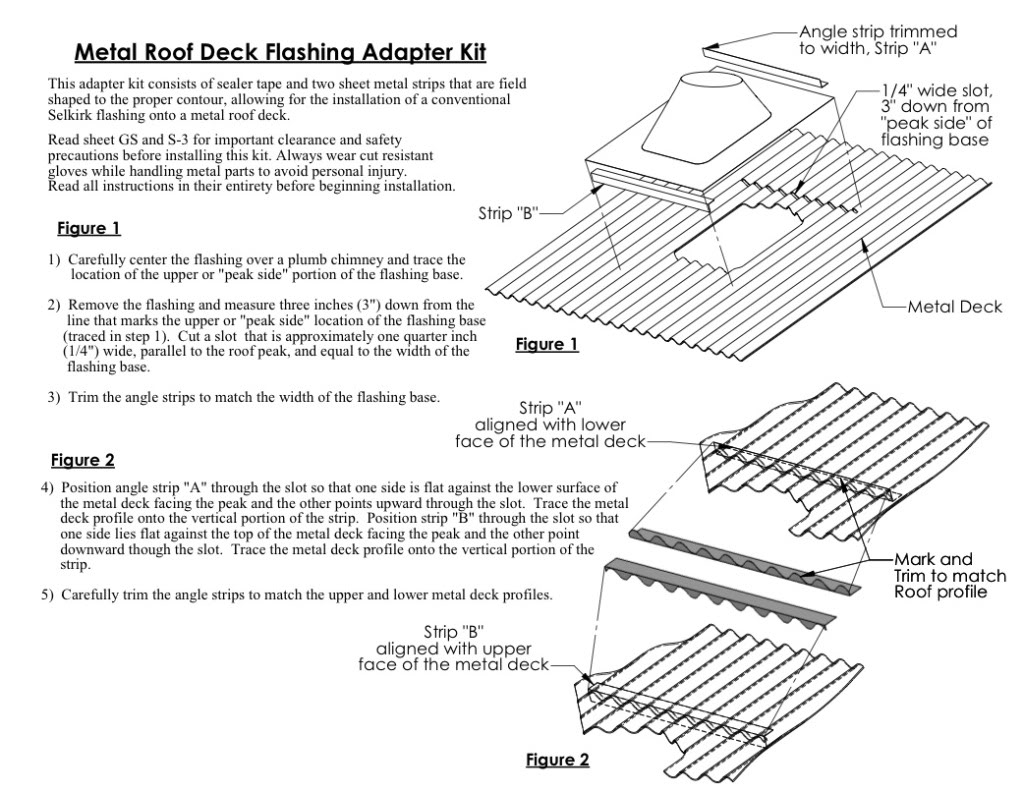

I didn't go with standing seam because it cost a lot more and required more support. Thanks for suggesting I do some searching. I'd just been taking my supplier's word for it that nothing was out there. SelKirk makes a kit. It is pretty much what I've been calling the "over" option. It's meant to be adapted in the field, so still requires some fab work.

Hmmm...link isn't working.

__________________

Main Entry: co de pen dence

Main Entry: co de pen dence - see codependency

co de pen den cy

Pronunciation: \kō-di-ˈpen-dən(t)-sē\

Function: noun

Date: 1979

: a psychological condition or a relationship in which a person is controlled or manipulated by another who is affected with a pathological condition (as an addiction to alcohol or heroin) ; broadly : dependence on the needs of or control by another

|

|

|

05-25-2009, 06:04 AM

05-25-2009, 06:04 AM

|

#8

|

|

Registered Member

Join Date: Mar 2009

Posts: 1,139

Country: United States

|

I just converted it to a jpeg and put it on photobucket.

Some people have difficulty getting the edges to work, apparently.

__________________

Main Entry: co de pen dence

Main Entry: co de pen dence - see codependency

co de pen den cy

Pronunciation: \kō-di-ˈpen-dən(t)-sē\

Function: noun

Date: 1979

: a psychological condition or a relationship in which a person is controlled or manipulated by another who is affected with a pathological condition (as an addiction to alcohol or heroin) ; broadly : dependence on the needs of or control by another

|

|

|

05-25-2009, 07:01 AM

05-25-2009, 07:01 AM

|

#9

|

|

Registered Member

Join Date: Apr 2008

Posts: 6,624

Country: United States

|

It looks similar to standing seam and I suspect that standing seam flashing would work. Glad you found something.

Got an email back from my dad, I guess it does always end up needing more work for standing seam / corrugated metal roofing...

Quote:

It all depends on what kind of penetration is involved i.e., pvc or

steel stack pipes (steel is code in MA for commercial buildings ),

square/rectangular vents, etc. Stack pipes are done with a 2 part sleeve

with a flange and a cap that fits over the circumfrence of the pipe.

This can be fabricated by the manufacturer or a metal shop .For other

types of round penetrations, the tin knocker usually makes a collar

about 6" high with a deck flange pitched to the roof with big enough

sides (hopefully) so that we can flash it the same way we would a boot

flashing on a shingle roof. The bottom of the flange must overlap the

metal roofing. For sq/rec penetrations, a flashing system is usually

provided by the hvac manufacturer or installer. In all cases, flashings

can be ordered with the roofing manufacturer or fabricated in the field.

The bottom line is that all pitched roofs are done with the same principles.

|

__________________

This sig may return, some day.

|

|

|

05-25-2009, 07:07 AM

05-25-2009, 07:07 AM

|

#10

|

|

Registered Member

Join Date: Mar 2009

Posts: 1,139

Country: United States

|

Thanks for asking him.

__________________

__________________

Main Entry: co de pen dence

Main Entry: co de pen dence - see codependency

co de pen den cy

Pronunciation: \kō-di-ˈpen-dən(t)-sē\

Function: noun

Date: 1979

: a psychological condition or a relationship in which a person is controlled or manipulated by another who is affected with a pathological condition (as an addiction to alcohol or heroin) ; broadly : dependence on the needs of or control by another

|

|

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

» Car Talk & Chit Chat

» Car Talk & Chit Chat |

|

|

|

|

|

|

|

|

|

|

» Fuelly iOS Apps

» Fuelly iOS Apps |

|

|

» Fuelly Android Apps

» Fuelly Android Apps |

|

|

|

|

|