I'll add more/clean/upload pics later.

This is a howto on swapping a VW diesel engine into a gasser body. Imo, it's way better to pick up a beat to hell diesel, a clean/dead gasser, and swap the diesel motor into the clean car than pay the obscene premiums these cars are pulling on the market. In fact, the best bet would be to send the diesel engine in as a core to the owner of vwdieselparts.com, get "The Kit" and assemble your own rebuilt engine before putting it into the gasser bunny. This should cost ~$1100 plus the cost of the diesel bunny or parts and gas bunny. For me, having a clean diesel bunny and parts to sell/scrap for ~$500, or a rebuilt diesel with a one year/unlimited mile warranty in a clean body for $1600, is worth it compared to buying something of unknown condition on ebay. Plus, having taken apart everything, repairs should be easy in the future.

Alright. First things first. Since we're putting a M/T/diesel in an auto/gasser, we'll need to swap over the steering rack as well as the engine/tranny because the shifter linkage bracket is welded to it. I've heard of bolt on shifter linkage brackets, but I'm guessing they were in pre 1980 cars. So that may be an option too. We also need the shifter and pedal cluster, and possibly the instrument cluster and wiring depending on whether we want to keep the stock glow plug system.

Tools - To pull the engine/tranny, I recommend a engine hoist since it makes things really easy. But, you can use two floor jacks since we'll only need to drop the engine on to the ground and lift the car over the engine. We'll probably need a universal joint driver to unbolt the brake booster bracket from the pedal cluster and swap those over. A 12-pt 12mm craftsman socket is recommended if the triple square axle bolts are rusted since these can be a pain to get out, and the craftsman triple square tool costs and arm and a leg. And the usual metric/standard wrenchs/sockets.

Gasser-

I'd start out by draining the fuel tank. Wally's World has a nice little multi-fluid transfer pump for $8, and imo, it's easiest to go through where the fuel sender is located than anyplace else. To get to this we need to remove the rear seat, which is done by removing a clip on each peg, so the brackets can slide off the peg, and the seat taken out. The sender is beneath a "lid" held on by three screws, remove those, and take a flathead/mallet to one of the edges on the sender cap. Remove the electrical connector, and hammer the cap lightly in a counterclockwise direction. It should pop up, and you can set it aside, giving you plenty of room to drain the tank with the pump.

Now we'll start on the engine. Drain/flush the coolant and unhook all hoses. Disconnect any electrical connectors, fuel lines, and throttle/transmission cables. Break the axle nuts loose, jack up the car, and remove the front wheels. Here's where it can be a PITA, if the triple square bolts that hold the axles are rusted, the best bet is to get the 12-pt 12mm craftsman socket and hammer it over the bolt heads. It'll dig channels into the outside, and allow us to turn them np. The socket has a lifetime warranty, so when we're done, or when it isn't useful, we can just take it back and exchange it. Now that the side of the axle connected to the transmission is free, we can angle it up and out, allowing us to remove the splined side from the wheels, and take the axle out. With an automatic transmission, the driver's side strut needs to be disconnected from the wheel doohickey, you'll know what I mean. As a caution, we shouldn't roll the wheels with the axle out because it may damage the front wheel bearings.

Next we'll disconnect the exhaust down pipe from the catalytic converter, and from the engine bay near the control arms. The engine/transmission/exhaust should now be disconnected from everything except for the four engine/transmission mounts. connect the engine to the hoist and make sure there is a little bit of tension on it. Now we can remove the rear transmission mount (two nuts), the front transmission mount (two bolts), and two side transmission mounts (one bolt each iirc). I usually leave the passenger side mount for last, and we will probably need to move the hoist up and down ever so slightly to jiggle the last bolt free. With everything disconnected, we can lower the engine onto a dolley or cardboard for easy removal taking care not to get the intake mani caught on the brake lines (don't try dropping it with two car jacks, trust me

). We then connect the hoist to the front engine mount or bumper brackets, your choice, and lift the car high enough to slide the engine out. Disconnect the fuel pump/lines/stuff by the tank and unhook the hard fuel lines from each set of tabs underneath the car. We can try to angle the hard lines past the brake booster/etc on the right side... and out the bottom of the engine bay, but it's a PITA, and imo, the best bet is to break them in the engine bay and drop the rest out. If we ever need them for another car, we can just cut/flare the broken ends and use them as is.

This next portion is only if the gasser is an automatic, M/Ts can skip it. Remove the tie rod ends from the rest of the suspension. The easiest way to do this is to remove the pin and loosen the bottom nut until it's flush with the bottom of the bolt, then,

with a floor jack and piece of wood, put a bit of pressure on the nut/bolt by jacking it up just a bit. Now take a big hammer, and using the wood as a guide, smack the knuckle until the tie rod end

pops out. Unbolt the two bushings in the middle, and remove the bolt connecting it to the steering, then pull it out. Remove the gear selector/line and pedal bracket (We need the universal joint driver to loosen the brake booster bolts) from the inside of the car.

Remove the instrument cluster if you want to use the diesel one, and pull any superfluous gasser bits you want/need to. Now, on to the diesel. *yawn*

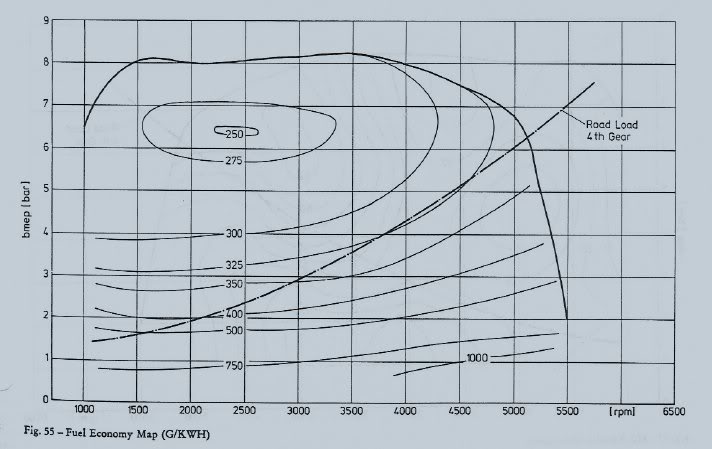

Edited for BSFC goodness.

According to my highly scientific, and even more highly lame calculations, with a stock Crr=.018, W=10000N, Cd=.45, A=1.67m^2, ro=1.225, 175/70R13s, no grade/no windm mpg from 25-70mph in 5mph increments is (62,65,63,61,55,48,48,44,41,38). With 205/70R14s over the same range it's (71,70,68,62,61,55,50,49,44,40). Assuming no P&G to help things out, just a steady cruise. With P&G at a 30mph average and 300g/kwh, mileage should be ~80mpg. With LRR tires, this jumps to ~130mpg over the same range.

Assuming Cd=.3, Crr=.009 (hello 3L Lupo). and tires are 205/70r14s, mileage goes like (90,89,83,86,80,75,70,65,60,57) from 25-70mph in 5mph increments. P&G at a 30mph average and 300g/kwh results in ~150mpg. W00t.