One month later, here is an update on the latest developments.

Electronic Control Unit - Exhaust Gas Recirculation Fixation

As I mentioned in my last post, the mechanic I took the car to told me that the EGR valves were not functioning properly, because of an ECU failure. I bought a replacement P07 ECU on ebay which was supposedly tested and fully functional for $80. Before swapping the ECU out, I went through the EGR valve troubleshooting steps on 11-34 to 11-39 of the 92-95 Civic Repair Manual, and indeed the EGR was not grounded properly. After swapping the ECU with its replacement, the same test indicated that it was now grounded properly. I took it back to get its emissions tested again, and the results were not that great. The NOx emissions were improved slightly (closer to 200, down from 300-800). The HC emissions at 25mph was improved slightly also, but still over limits. The lowest PPM measured was 92 at 25mph, and the max allowed to pass is 62.

Head Gasket Replacement

So my dad and myself went forward with the head gasket replacement plan. As I said above, the mechanic indicated that there was no oil pressure at the Spool Valve assembly, and that this was why the VTEC system was not engaging properly, and the reason for the CEL Code 22 (Oil Pressure Switch) coming on when engine conditions would normally result in VTEC crossover, if everything were working properly. The mechanic thought that the reason for the lack of oil pressure might be because of an improper head gasket being previously installed, resulting in oil being blocked from coming through passages that it needed to, in order to get to the Spool Valve Assembly. This always seemed a little far fetched to me, but we went ahead with the investigation.

So armed with an empty day in front of us, and a box of tools (10mm, 12mm, 14mm wrenches and sockets, torque wrench for torquing down the head bolts again, some pliers and wrenches and so forth), we started tearing apart my engine. I will include some pictures by way of visual explanation, as other people might find it useful.

We roughly followed the instructions for Cylinder Head Removal starting on page 6-28, and Cylinder Head Installation, starting on page 6-53 of the Repair Manual. We disconnected all hoses and electrical connections to the head. We drained the coolant (the engine coolant drain under the exhaust manifold was seized, so we had to use the radiator drain, and the lowest coolant hose going into the engine block to drain the coolant to a level below the head gasket. This ended up working fine.)

We removed the Timing Belt cover, and the valve cover, and set the Cam Pulley so that the "UP" mark was straight up, so that the first piston was at Top Dead Center. We were able to turn the engine over with just a wrench on the Cam Pulley retaining bolt, but we ended up moving it into position by putting the car into gear and rolling backward (reverse moves the cam pulley counter-clockwise, 1st or 2nd, clockwise). The Cylinder Head Removal instructions in the repair manual tell you to remove the timing belt completely, but my dad thought we could mark the exact position it was in, and just remove the Cam Pulley section of the belt, thus saving ourselves some work. This actually was successful. Here is a picture of what we did.

It looks pretty bad, but it actually worked okay. First we marked the Timing belt with Duct Tape in the exact positions of the 9:00 and 3:00 marks (using the "UP" mark as 12:00). This was accurate enough to put it back in the exact same divets. We unbolted the Cam Pulley, and pulled it out, while simultaneously sliding the timing belt back towards the block. Using two sets of hands, we kept upward pressure on the timing belt as we removed the pulley. We then had to figure out a way to lock it in place, so that it wouldn't get loose and slip on the Belt Tensioner or Drive Pulley. We used an available thing, and jammed it gently into the right side, which kept it from slipping back, and then another available thing on the other side, folding over (but not crimping) the slack at the top. This held it there.

We removed the Head Bolts in the order specified so as to not warp the head, and kept them in order. Note that removing the valves is not necessary for the removal of the head block.

This is the engine with the head removed... The cylinders don't seem too worn, as indicated by the lack of a ridge around the top, according to my dad.

To my great lack of surprise, the head gasket was the correct type for the engine, being exactly matched to the replacement that I bought.

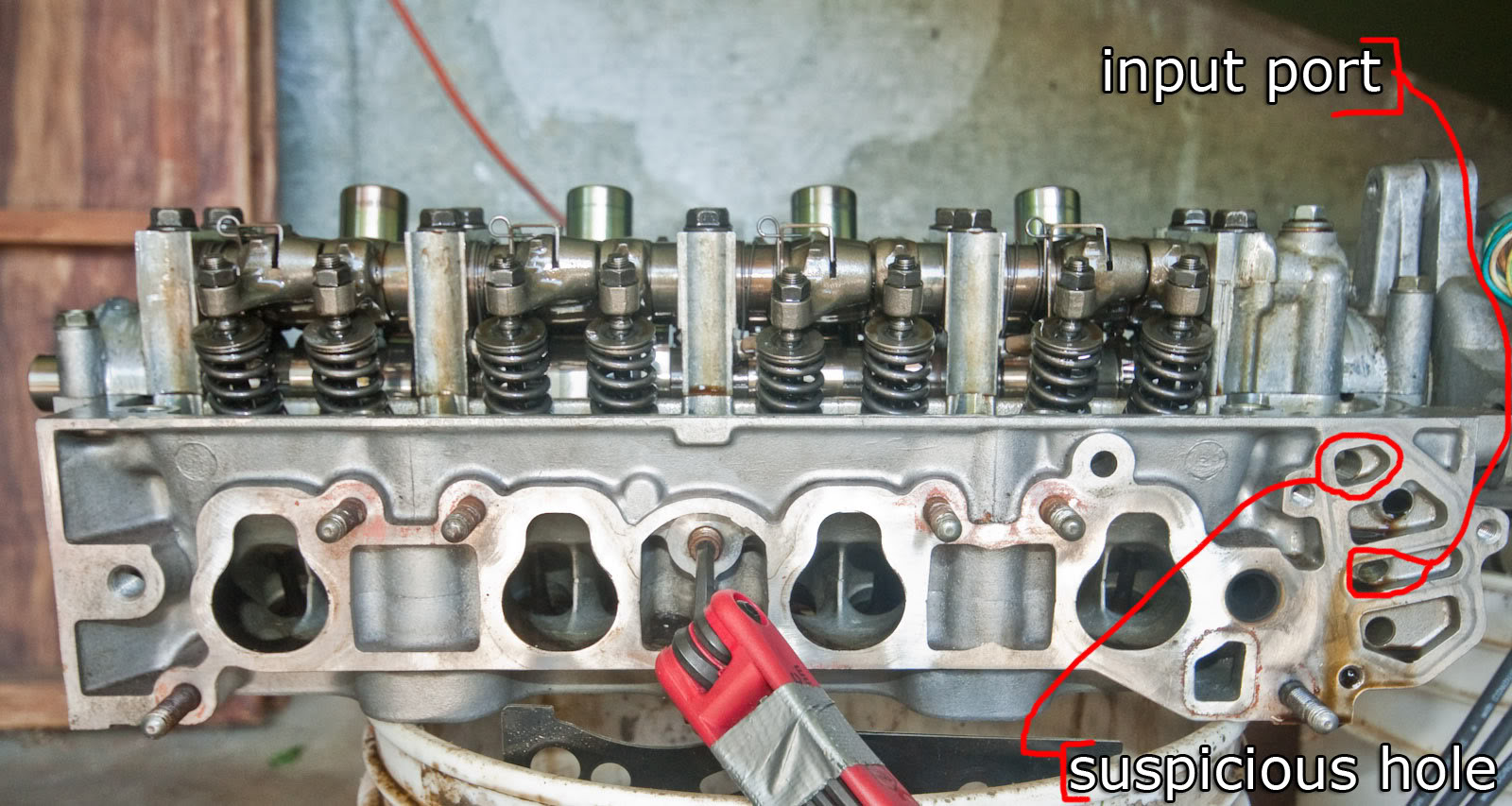

Here is the bottom of the head, displaying all of the holes in their correct locations. We were somewhat disheartened by this discovery, but at least we ruled it out as a cause of the VTEC problem.

We spent a while investigating the oil passages going to and from the Spool Valve Assembly, using a small air compressor to establish flow destination.

You can see the oil passageways that go into the Spool Valve Assembly at the right of this picture. The middle passage (2nd from the bottom) is the main input port. Oil comes up through an internal passageway from the input port that I assume comes up from the main oil reservoir. (this passageway goes past on the inside where the red allen wrench is stuck in there).

This passageway is visible here, as the little nipple looking thing in the center on the rear between pistons 2 and 3.

The passage third from the bottom goes into the rod above the camshaft that the valve rocker arms are attached to. I think this is where oil pressure goes in order to switch the VTEC on and engage the higher cam profile. We reasoned that the function of the Spool Valve Assembly was to switch between allowing and disallowing high oil pressure to get into this passageway.

I can't remember where the bottom passageway went.

The real interesting passageway though is the top passageway, which as you can see goes directly into the valve chamber on top of the head.

We re-assembled the engine with the new head and manifold gaskets, and after everything was in place except for the valve cover, we started the engine. It started right up, but after a second, my dad noticed oil starting to pour out of that top hole in the Spool Valve Assembly into the valve chamber. He thought this to be very odd, thinking that oil was going to be coming out of the tube that the rocker arms attach to, in order to lubricate them.

We immediately turned off the engine and investigated to make sure everything was on correctly and that we hadn't forgot anything. It was, and we hadn't.

A Question About Oil Flow

The mechanic was babbling on about how someone drilled a hole in the head near the spool valve assembly. At the time, I was just very confused, but I am wondering if this hole that goes from the top chamber of the Spool Valve Assembly into the Valve chamber on the top of the head block might not supposed to be there? Has anyone here seen the inside of a D15Z1 head block, and might they be able to tell me if that hole is supposed to be there? I can't seem to find any oil flow information on the engine. What do you all think?

Valve Adjustment

After the head was back on (and before we started the engine), we adjusted the valves. Interestingly enough, many of them were very tight.

I had adjusted them with a friend soon after buying the car, in order to see if the strange clicking sound that the car makes when in gear and accelerating (but not decelerating), and only when the car is started cold, was being caused by the valve lash being loose.

My friend had tightened them a bit too much, I think, because all of the valves were tight, and the exhaust valves on two different cylinders were almost 3/4 of a turn tight.

I'm not sure if the problem of tight valve lash would be enough to make the engine misfire and run rough enough to fail emissions, but the engine definitely feels like it runs smoother now. Before there was a rhythmic hesitation in the engine as it idled (very subtle, but noticeable), which is gone now.

Tightened valves still doesn't explain the abnormally elevated HC levels on the 25mph portion of the emissions test but not the 15mph portion... does it?

I am wondering if I should go back and get it retested again to see if the valve issue helped at all.